Concrete is a common building material used in architecture and construction. It is a mixture of cement, sand, aggregate, and water that can be poured or formed into a variety of shapes and sizes. Concrete has many advantages as a building material, including its strength, durability, and versatility.

Types of Concrete

Normal Strength Concrete: Also known as traditional or regular concrete, this is the most common type of concrete used in construction and has a compressive strength between 20-40 MPa. It is used for most general applications, such as foundations, walls, and floors.

Lightweight Concrete : This type of concrete is made by replacing the coarse aggregate with lightweight materials, such as expanded clay, shale, or slate. It is used for applications where weight is a concern, such as for roofing and precast concrete elements. This type of concrete is commonly used to build window panels, roofs and floor slabs.

High Density Concrete is also called heavyweight concrete and are made of high density crushed rocks as coarse aggregates such as Barytes. This type of concrete are commonly used for counterweights and other similar usage which requires high density properties and has a compressive strength greater than 40 MPa and is used for structures that require a higher strength, such as high-rise buildings and bridges.

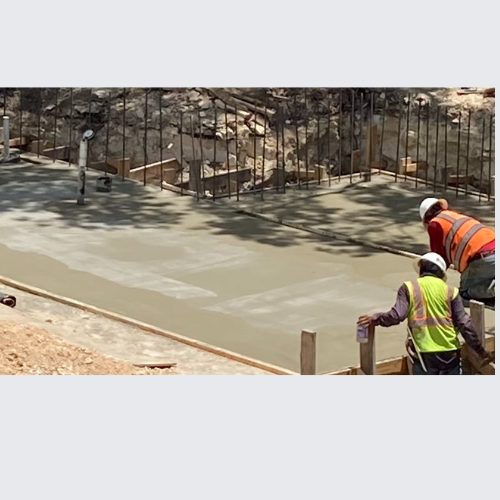

Reinforced Concrete or Reinforced Cement Concrete (RCC) is considered critical concrete type and is commonly used concrete type in modern construction. This type of concrete incorporates steel reinforcement (usually in the form of bars or mesh) to enhance its tensile strength. The combination of concrete's compressive strength and steel's tensile strength makes it ideal for structures like bridges, columns, beams, and slabs.

Precast is made by casting concrete into molds or form in the factory according to specifications and it deliver to the construction site. They are made up of coarse and fine aggregates, cement, water and admixtures. Some of the example of precast concrete are concrete blocks, precast walls and pole, fence and staircase units.

Image Courtesy: SpanWright | Flickr

Prestressed concrete is made by casting concrete into preassembled molds or forms using a combination of rebar and steel cable reinforcement. it is usually used for constructing floor beams, bridges, roofs and pile, runways and other structural elements to reduce cracking and deflection.

Glass Reinforced Concrete or Glass Fiber Reinforced Concrete (GFRC) is a mixture of cement, glass fiber, fine sand and an acrylic polymer for elasticity. It is commonly used to make cladding panels and concrete countertops. It provides a better insulation properties, fire and weather resistance as well as durability.

Image Courtesy: https://www.concretenetwork.com/glass-fiber-reinforced-concrete/

Air-Entrained Concrete is a plain concrete entrained with controlled amount of air which can be achieved by adding a foaming agents or air entraining agents such as fatty acids, alcohols and cohesive substance/resins.

Image Courtesy:https://dreamcivil.com/air-entraining-cement/

Self-Compacting Concrete (SCC) :Designed to flow and settle into place under its weight, without the need for mechanical vibration. It is particularly useful for complex shapes, congested reinforcement, and hard-to-reach areas, as it can easily fill voids and gaps without segregation. It is used for architectural applications where a smooth, consistent finish is desired, such as for decorative walls and facades.

Smart Concrete provides a various way to monitor the condition of reinforced concrete structures ensuring the structural safety, resiliency and structural integrity.

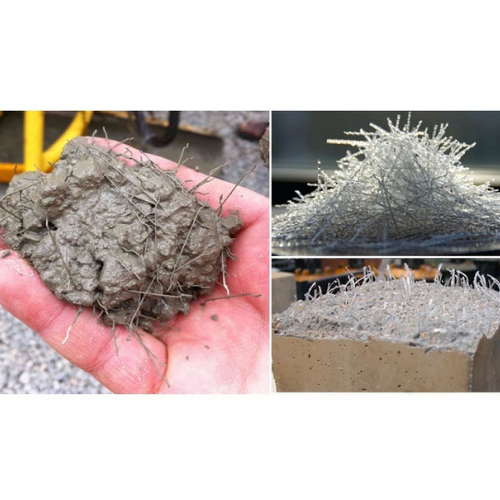

Fiber Reinforced Concrete ( FRC) : This type of concrete contains fibers, such as steel or synthetic fibers, glass, or natural fibbers, which are added to increase its strength and durability. It is used for applications where extra strength and durability are required, such as for retaining walls and precast concrete elements.

Image Courtesy: https://dailycivil.com/?s=fiber+reinforced+concrete

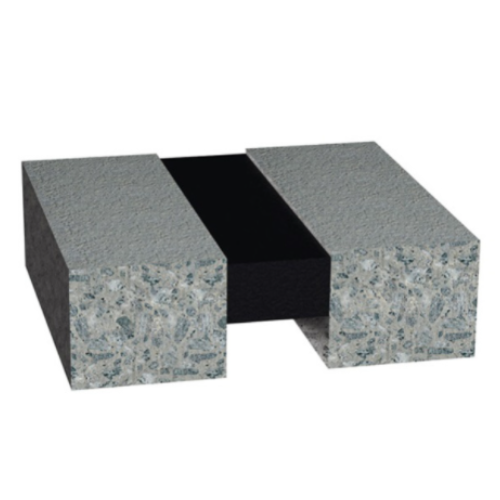

Polymer Concrete : Type of concrete that is modified by the addition of polymer resins to the traditional concrete mixture. The polymer resins act as a binder, replacing or supplementing part of the cement used in conventional concrete. This modification results in a material with enhanced properties, making it suitable for various applications in construction and infrastructure projects. is a type of concrete that uses polymer binders or liquid resins instead of cement.

Image Courtesy:https://dailycivil.com/polymer-concrete/

Benefits of Concrete:

Strength and durability: Concrete is an incredibly strong and durable material, able to withstand heavy loads, extreme weather conditions, and natural disasters such as earthquakes and hurricanes. This makes it an ideal choice for buildings that need to be strong and long-lasting.

Versatility: Concrete can be molded into almost any shape, allowing architects to create unique and visually striking buildings. It can also be used to create a wide range of finishes, including smooth, textured, polished, and exposed aggregate.

Fire resistance: Concrete is highly resistant to fire, making it a safe choice for buildings in areas prone to wildfires or other types of fires.

Sound insulation: Concrete walls and floors can provide excellent sound insulation, helping to reduce noise pollution both inside and outside the building.

Energy efficiency: Concrete has high thermal mass, which means it can absorb and store heat energy. This makes it an energy-efficient material that can help to reduce heating and cooling costs.

Sustainability: Concrete is made from natural materials and is recyclable, making it an environmentally friendly choice for construction.

Low maintenance: Concrete is easy to clean and requires minimal maintenance over its lifespan, which can be up to 100 years or more.

Conclusion:

The broad spectrum of concrete types available in architecture highlights the adaptability and versatility of this fundamental construction material. From the traditional use of normal concrete for general structures to specialized options like pre-stressed and high-density concrete for demanding applications, each type serves a unique purpose based on its distinctive properties.

In the realm of architecture, the diverse types of concrete provide architects with a broad range of materials to create enduring and captivating structures. The ongoing development and exploration of concrete technology promise even more innovative applications in the construction industry, shaping the future of architectural design.