Zip sheathing is a popular building material that is used in a wide range of construction projects. It is known for its strength, durability, and moisture resistance, making it an ideal choice for many builders and architects. In this blog post, we will explore what zip sheathing is, how it is made, and the benefits it offers in creating a tight building envelope.

What is Zip Sheathing?

Zip sheathing is a type of structural wall panel that is designed to replace traditional plywood or OSB sheathing in residential and commercial construction. It is made from an engineered wood panel that is laminated with a water-resistant barrier to create a single, continuous layer that provides structural support and acts as a moisture barrier.

How is Zip Sheathing Made?

Zip sheathing is made using a process called laminating, which involves bonding multiple layers of wood with an adhesive. The top layer is usually a panel of engineered wood, such as oriented strand board (OSB) or plywood, while the bottom layer is a layer of water-resistant barrier material, such as a polymer-based film. The result is a strong, moisture-resistant panel that provides both structural support and a moisture barrier in one product.

What is a Moisture Barrier in a Building?

A moisture barrier is a layer of material that is designed to prevent moisture from entering a building. Moisture can cause damage to building materials, promote the growth of mold and mildew, and reduce the energy efficiency of a building. A moisture barrier is an essential component of any building, as it helps to protect the building from moisture damage and ensure that it remains structurally sound and energy-efficient over time.

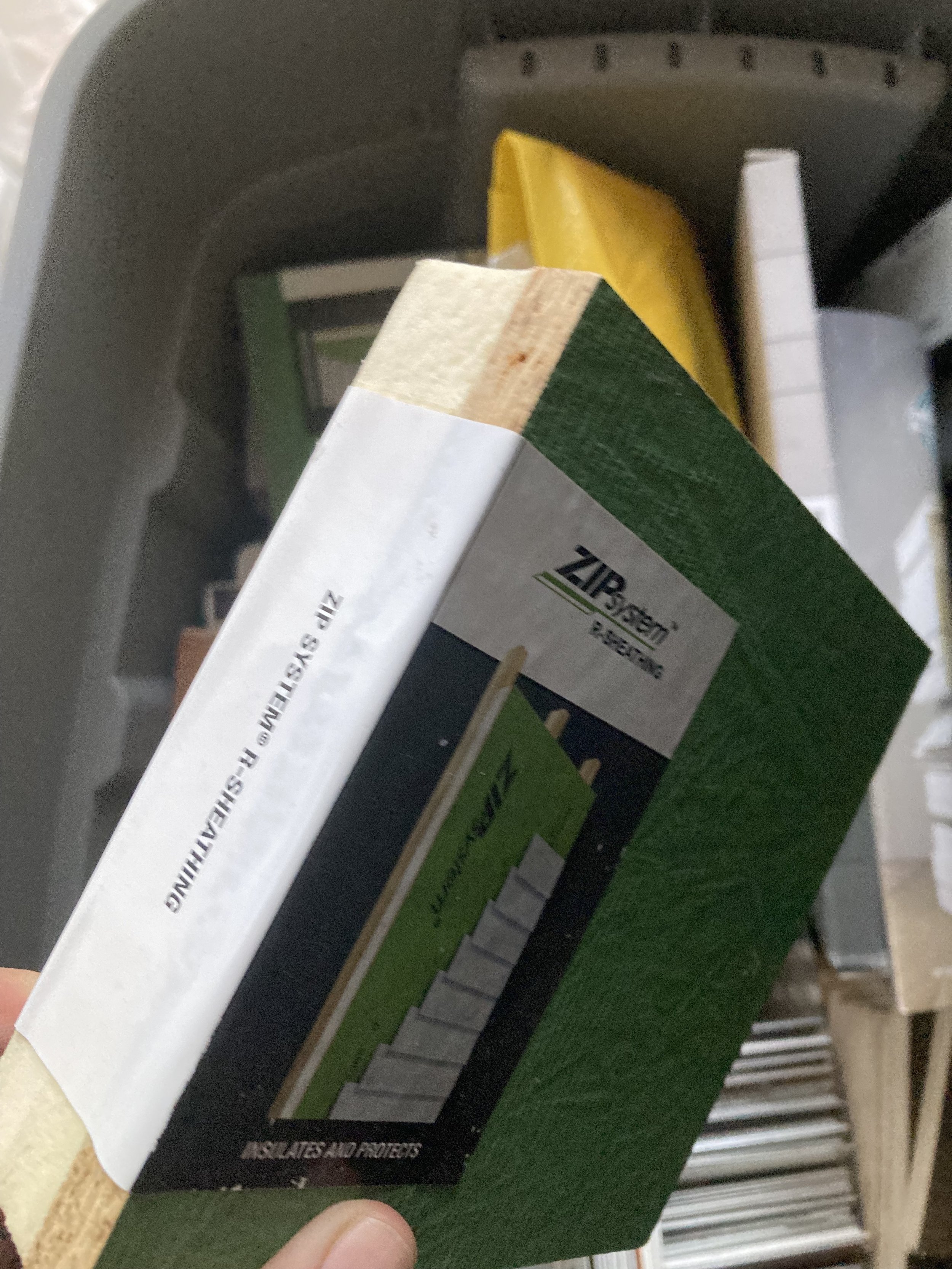

R-Panel Zip Sheathing Products

R-panel zip sheathing products are a type of zip sheathing that is designed to provide superior insulation for buildings. These products are made with an extra layer of rigid foam insulation that is laminated to the back of the panel, providing additional insulation and increasing the overall energy efficiency of the building.

ZIP R Panel

Zip R panel provides a continuous insulation barrier for increased energy performance. It comes in a variety of insulation thicknesses depending on the desired R-value one wishes to achieve.

Zip Tape and Liquid Flashing

Zip tape and liquid flashing are two products that are often used in conjunction with zip sheathing to create a tight building envelope. Zip tape is a specially designed tape that is used to seal the seams between zip sheathing panels, while liquid flashing is a type of liquid sealant that is used to seal around windows, doors, and other openings in the building envelope.

Advantages of Zip Sheathing

Moisture resistance: The water-resistant barrier on zip sheathing helps to prevent moisture from entering the building, reducing the risk of moisture damage and mold growth.

Structural support: Zip sheathing provides a strong, stable base for the exterior cladding of the building, helping to improve the overall structural integrity of the building.

Energy efficiency: R-panel zip sheathing products, in particular, provide superior insulation, reducing heating and cooling costs and improving overall energy efficiency.

Tight building envelope: When used in conjunction with zip tape and liquid flashing, zip sheathing can help to create a tight building envelope that is less prone to air leaks and drafts, improving indoor air quality and comfort.

Conclusion and Outlook

Zip sheathing is a versatile and durable building material that provides a number of benefits to builders and architects. Its moisture resistance, structural support, and energy efficiency make it an ideal choice for a wide range of construction projects. As building codes and energy standards continue to evolve, it is likely that zip sheathing and other tight building envelope solutions will become even more popular in the years to come.

Additional Resources:

https://bmc.a.bigcontent.io/v1/static/Huber_ZIP_System_Brochure_2020/.pdf

https://www.huberwood.com/zip-system/insulated-r-sheathing

https://www.mccraylumber.com/benefits-of-zip-system-r-sheathing/